Geological surveys play a crucial role in the success of construction projects, providing essential insights into the subsurface conditions that can significantly impact the planning, design, and execution phases. Understanding what lies beneath the surface is vital for ensuring the safety and stability of structures. Here are more reasons why getting geological surveys in Harvey, LA, has become even more imperative in the region:

Understanding Subsurface Conditions

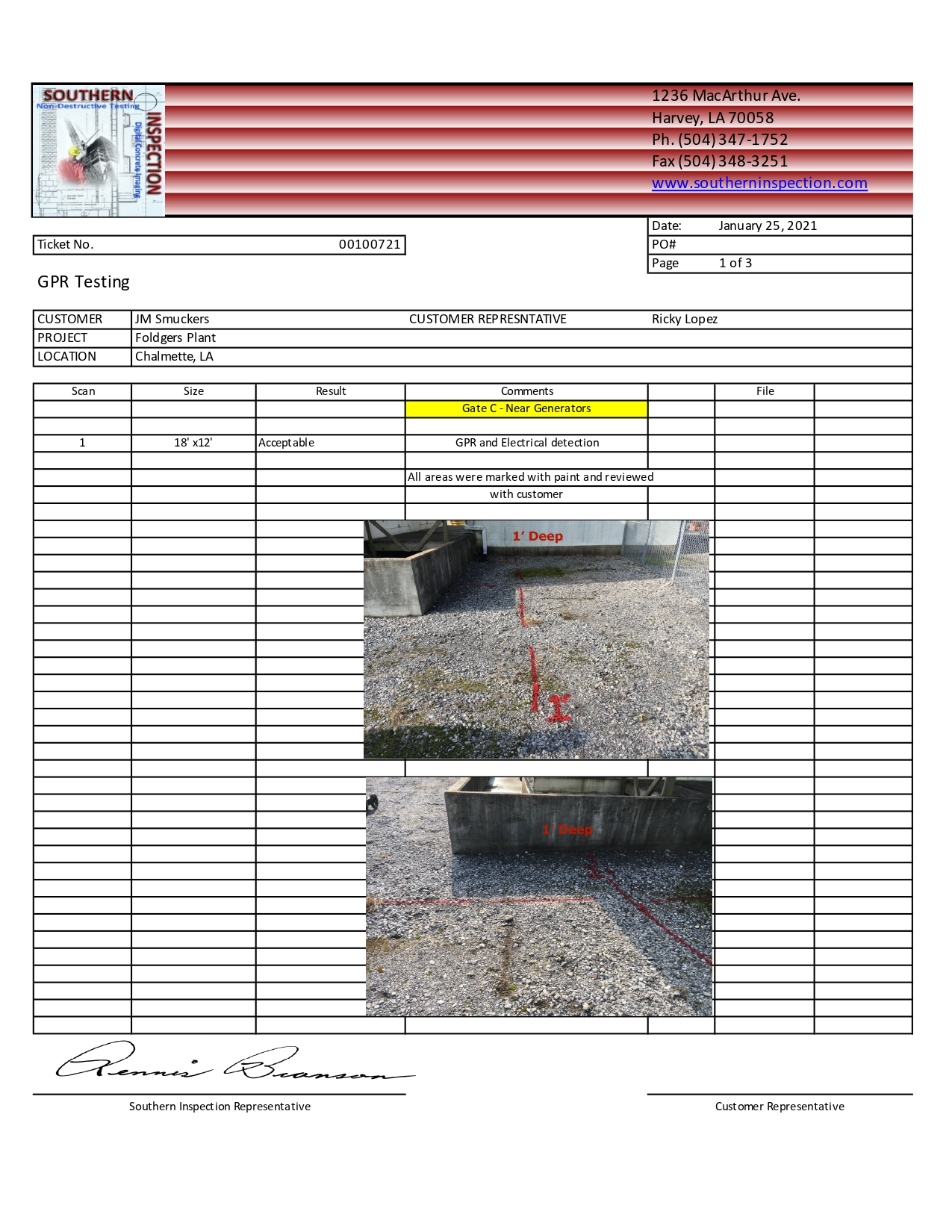

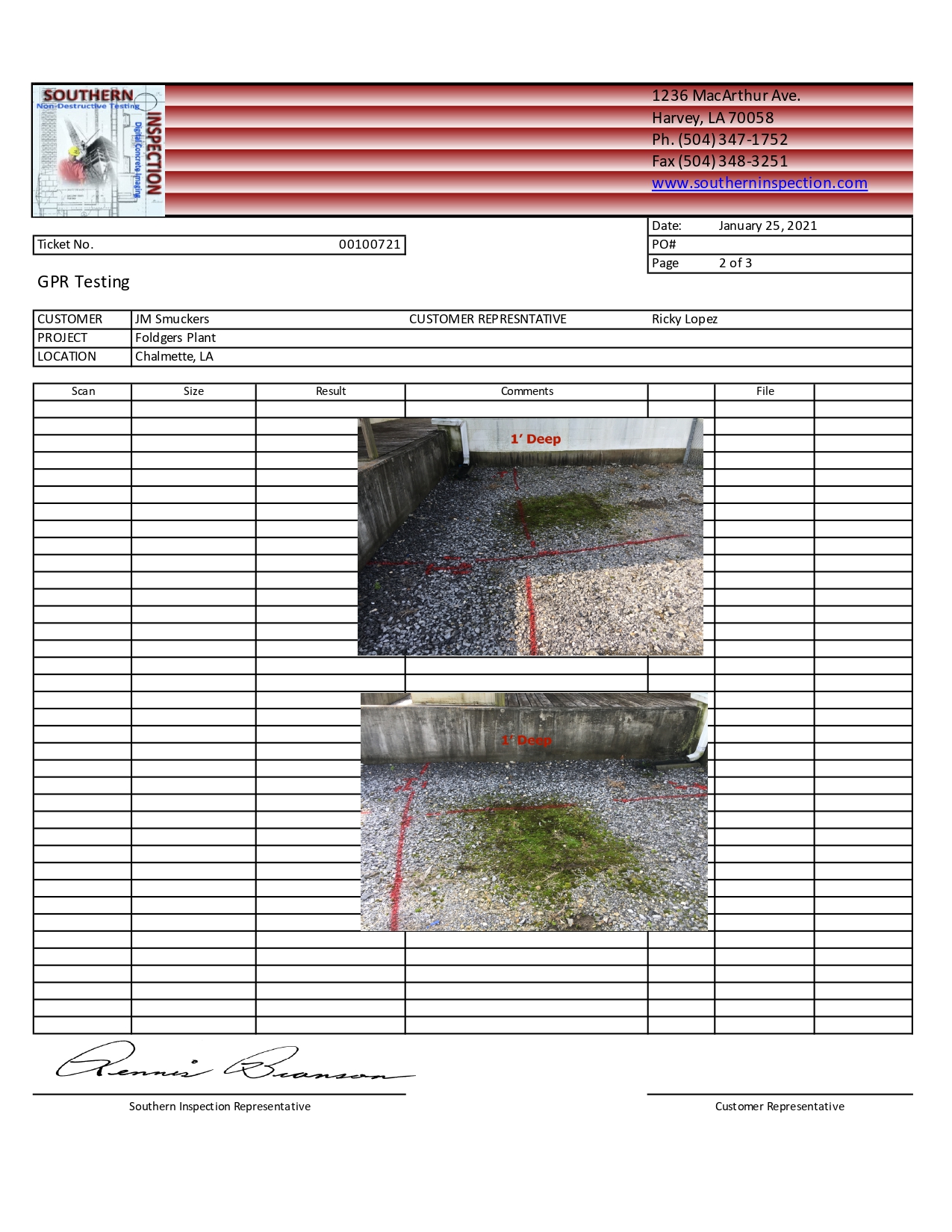

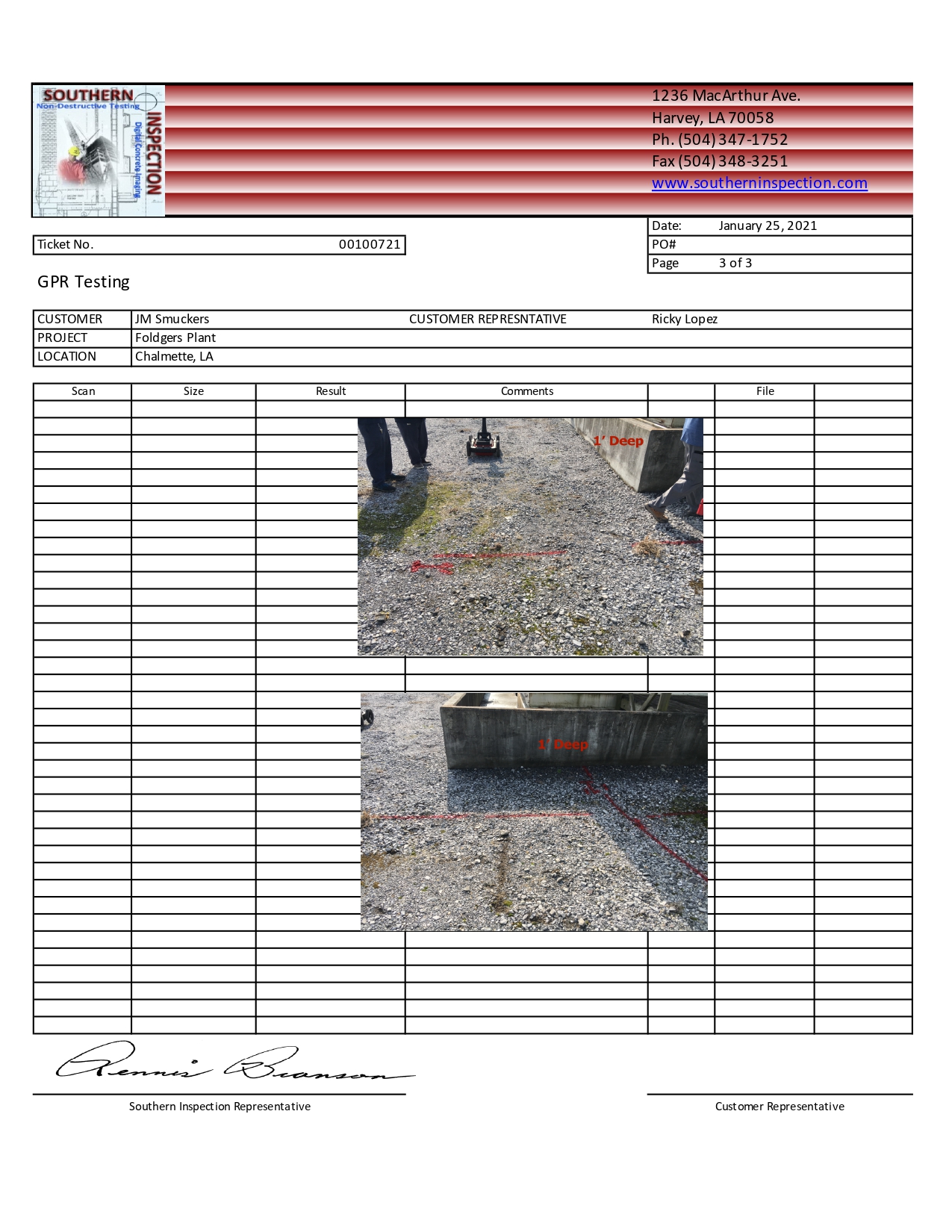

One of the primary benefits of conducting geological surveys is the ability to identify and assess subsurface conditions. These surveys utilize various methods, including ground penetrating radar (GPR), to detect anomalies, locate potential hazards, and evaluate soil stability.

By employing GPR technology, construction professionals can gain a detailed view of underground features without invasive drilling techniques. This non-destructive method not only saves time and resources but also minimizes disturbances to the surrounding environment.

Mitigating Risks

Geological surveys help in mitigating risks associated with construction projects. Identifying issues such as soil erosion, groundwater levels, and the presence of underground utilities can prevent costly delays and safety hazards. By proactively addressing these challenges, developers can create robust designs tailored to the specific geological conditions of Harvey, LA, ultimately leading to successful project completion.

Informing Design Decisions

Accurate geological assessments inform critical design decisions. By understanding the material properties and behaviors of the subsurface, engineers can create foundations and structures that are both safe and sustainable. This knowledge empowers construction teams to plan for necessary reinforcements or alterations, ensuring that the outcome meets regulatory standards and client expectations.

In summary, geological surveys are indispensable tools for construction projects. By utilizing methods such as ground penetrating radar, professionals can make informed decisions that enhance safety, reduce risks, and improve overall project outcomes.