Metallurgical Testing in Harvey, LA

At Southern Inspection, we offer comprehensive metallurgical testing in Harvey, LA. Our testing capabilities encompass a range of processes that enable us to evaluate project materials, test adherence, identify contaminants, and detect material failures. We provide you with valuable insights derived from several testing mechanisms.

Our corrosion testing services are particularly critical in determining pipe wall thickness by scientifically determining the accelerated rate and intensity at which any metal type will corrode. This service is also beneficial for material selection for tubes, tanks, bridge supports, and other types of structural steel beams and pilings.

Our corrosion testing services are particularly critical in determining pipe wall thickness by scientifically determining the accelerated rate and intensity at which any metal type will corrode. This service is also beneficial for material selection for tubes, tanks, bridge supports, and other types of structural steel beams and pilings.

Corrosion testing surpasses mere visual inspection, which is often inadequate in determining a material's interior condition. This service is necessary to prevent dangerous structural failures during construction applications and completed projects.

Additionally, our construction testing company offers high-end machined products crafted to our customers' specifications regardless of their industry. Our experienced craftsmen utilize the latest technology, material specifications, and construction codes to offer the most suitable end products for tools, parts, and repair work requested by our customers.

Our customers often request visual material inspection from our site, remote work environments, and on-site. Our broad industry knowledge ensures proper and accurate identification of material conditions to provide them with the best results.

If our staff identifies complex issues requiring construction testing services, it is immediately reported to our customers. Our construction testing company goes above and beyond to ensure your job is done even in the hardest-to-reach inspection sites.

Positive Material Identification (PMI)

Our construction testing company provides accurate and rapid Positive Material Identification (PMI) testing services. Our nondestructive testing method analyzes metallic alloys by reading the quantity percentages of constituent elements, using a portable X-ray fluorescent analyzer to determine the elemental composition of the material.

We apply PMI for ferrous and non-ferrous metallic materials, stainless steels, Monels, Inconels, Hastelloys, aluminum alloys, nickel-based alloys, and exotic materials. Our expertise in PMI allows us to verify material compliance in power and petrochemical industries; inspect valves and components, pipes, fittings, and welds; and verify pressure vessels' compliance, plate materials, and structural steel.

Our portable digital technology is used on-site, is highly accurate, and certifies items requiring NACE MR0175/ISO 15156 without testing on the sample. However, care must be taken to ensure the specimen's surface represents the entire material and that the analyzer maintains surface contact with the material.

Limitations of PMI include the element's limited depth of penetration, only identifying the alloys listed in the manufacturer's library, and material verification restricted to temperatures below 200°F unless specialized equipment is available. Moreover, the identification of small amounts of a specific element can be challenging, and X-ray fluorescence cannot identify carbon, sulfur, or phosphorous.

We conduct PMI using the latest portable analyzers, such as X-ray fluorescence (XRF) and Optical Emission Spectrometry (OES), and our inspection report summarizes the test results. We are a reliable construction testing company that cares about providing accurate and rapid PMI.

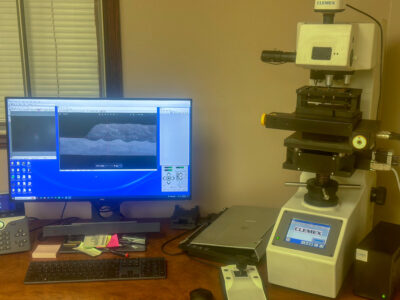

Hardness Testing

Hardness is a fundamental property of materials that determines their resistance to plastic deformation, including penetration, bending, scratching, abrasion, or cutting.

Measurement of Hardness:

Hardness is not an intrinsic property defined by fundamental units of mass, length, and time. Instead, it is measured through established procedures. Traditionally, hardness has been assessed by evaluating resistance to scratching or cutting. For example, material B may scratch material C but not material A.

This relative hardness assessment can be further aided by referencing the Moh's Scale, which ranks materials based on their ability to resist scratching. Other methods, such as the file test, involve rubbing a file with a desired hardness on the test material's surface. If the file slides without marking the surface, the test material is considered harder than the file. Conversely, if the file bites or marks the surface, the test material is considered softer.

However, these relative hardness tests have limitations and do not provide precise numeric data, especially for modern metals and materials. A common method of obtaining a hardness value involves measuring the depth or area of an indentation made by a specific indenter shape with a particular force applied for a specific time.

Brinell, Vickers, and Rockwell are the three principal standardized test methods for expressing the hardness-impression size relationship. Each method is further divided into various scales, determined by the combination of applied load and indenter geometry.

Hardness Test Methods:

- Rockwell Hardness

- Rockwell Superficial Hardness

- Brinell Hardness

- Vickers Hardness

- Microhardness

- Moh's Hardness

- Scleroscope Hardness

- The Durometer

Hardness Conversion or Equivalents:

Converting hardness values between different methods and scales is not mathematically exact for a wide range of materials. Factors such as varying loads, indenter shapes, specimen homogeneity, cold working properties, and elastic properties complicate the conversion process.

Therefore, any tables or charts provided should be considered as offering approximate equivalents, particularly when converting to a method or scale that may not be physically feasible for the specific test material and cannot be verified. For example, converting an HV/10 or HR-15N value on a thin coating to the HRC equivalent may pose challenges.

Corrosion

Corrosion Testing to:

- ASTM G48 (Stainless Steels and Related Alloys)

- ASTM G66 (Aluminum-Magnesium Alloys)

- ASTM G67 (Aluminum Alloys)

Ferrite Testing

Ferrite Testing is a nondestructive testing method used to analyze the ferrite content in austenitic stainless steel and duplex materials. This analysis provides critical data for assessing material corrosion susceptibility, mechanical properties, and service suitability and reliability.

To ensure accurate ferrite testing, it is necessary to have a minimum material thickness and specimen size. Test results are interpreted by current specifications and/or customer requirements. Reports are accompanied by drawings when necessary to identify the tested locations.

At Southern Inspection, a leading construction testing company specializing in metallurgical testing, we utilize ferrite testing for the inspection of various materials, including:

1. Austenitic Stainless Steel/Duplex Stainless Steel:

- Welds (Tubing, Etc.)

- Normal Construction Steel with Austenitic Chrome Alloy Steel Welded Cladding (E.G., Boilers, Vessels, Etc.)

2. Weldments, Castings, Forgings, Weld Overlays, Wrought materials

3. Weld Materials:

- Butt/Fillet Welds

- Category A-D Welds

- Stainless Weld Overlays on Non-Ferrous Interfaces

4. In-Service and In-Construction Components

Advantages

- Rapid and Accurate Analysis

- Highly Portable Digital Technology

- Variable Calibration in Both Ferrite Number (FN) and % Ferrite (FN) Using AWS Standards

- Testing Instrument Meets All Requirements Of ANSI/AWS A4.2 and DIN EN ISO 8249

- Calibration Is Traceable to Internationally Approved IIW Secondary Calibration Standards

Limitations

- Not Recommended for Materials at Temperatures Greater Than Approximately 125°F

- Surface Preparation Is Crucial for Accurate Results

- Requires a Minimum Material Thickness and Specimen Size

- Specimen Shape May Have a Negative Effect on the Obtained Results, but Correction Calculations Can be Performed in Some Instances

Turn to our construction testing company for reliable and comprehensive metallurgical testing services. As a construction testing company, we specialize in providing ferrite testing and other methods, such as microetch and chemical analysis, to ensure the quality and integrity of materials in various construction and industrial applications.